manufacturing execution system rfid By embracing RFID work in process solutions, RFID inventory management . Key Takeaways. NFC stands for "Near Field Communication," and it enables devices to communicate wirelessly over a short distance. NFC is most commonly used for mobile payments, such as Google Pay and Apple Pay. .

0 · Real

1 · RFID in Manufacturing

2 · RFID

3 · Enhancing Manufacturing Efficiency and Control with RFID

CardSession requires the presence of an NFC reader, which isn’t supported in Simulator, to perform an ISO 7816 card emulation session. You can test with the following configurations: Your iPhone is running iOS 18.2 or later; Your iPhone .

This paper presents an RFID-enabled real-time manufacturing execution system . By embracing RFID work in process solutions, RFID inventory management .

This paper presents an RFID-enabled real-time manufacturing execution system (RT-MES). RFID devices are deployed systematically on the shop-floor to track and trace manufacturing objects and collect real-time production data. Disturbances are identified and controlled within RT-MES.

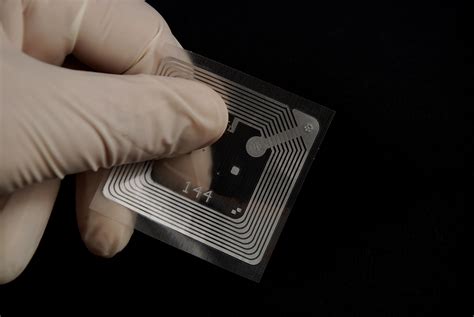

credit card nfc

By embracing RFID work in process solutions, RFID inventory management systems, RFID tags, RFID asset tracking solutions, and comprehensive RFID systems, manufacturers can unlock new possibilities for innovation, collaboration, and . Here’s a rundown of the 8 best manufacturing execution systems based on pricing, customization options, and key features like production scheduling and workflow modeling. FactoryTalk: Best Overall. ShopVue: Best for Labor Management. ShiftWorx: Best for Machine Monitoring. HYDRA: Best for ISO and FDA Compliance. This paper presents a RFID enabled real-time manufacturing system which will incorporate five functions. These five functions will be integrated into an android based interface which reads and writes data to a cloud based database in real time. With RFID technology, tags, products, materials, parts, tools and so on can’t get lost in a manufacturing facility. And you don’t need people with scanners walking around trying to find and .

This research aimed to develop and test an integrated industrial information system, the CSR-OMO-PL, through hardware, software and RFID technology for real-time integration and optimisation in footwear production lines, resulting in visibility and interoperability during manufacturing execution.

Real

The radio frequency identification (RFID) technology is applied in a mixed-model assembly line to facilitate operational functionalities of the manufacturing execution system (MES), including data collection, document control, labor management, production process control, and performance analysis.Taking the textile industry as object, the design of manufacturing execution system based on RFID is presented by this paper. And it provide perfection system solution for enterprise realizing real-time informatization.

This paper introduces an RFID-enabled real-time manufacturing execution system (RT-MES) for improving DM shop-floor management level in the perspective of illustrating the RT-MES software design and implementation. This paper presents an RFID-enabled real-time manufacturing execution system (RT-MES). RFID devices are deployed systematically on the shop-floor to track and trace manufacturing objects and collect real-time production data. Disturbances are identified and controlled within RT-MES.

This paper presents an RFID-enabled real-time manufacturing execution system (RT-MES). RFID devices are deployed systematically on the shop-floor to track and trace manufacturing objects and collect real-time production data. Disturbances are identified and controlled within RT-MES.

By embracing RFID work in process solutions, RFID inventory management systems, RFID tags, RFID asset tracking solutions, and comprehensive RFID systems, manufacturers can unlock new possibilities for innovation, collaboration, and . Here’s a rundown of the 8 best manufacturing execution systems based on pricing, customization options, and key features like production scheduling and workflow modeling. FactoryTalk: Best Overall. ShopVue: Best for Labor Management. ShiftWorx: Best for Machine Monitoring. HYDRA: Best for ISO and FDA Compliance.

This paper presents a RFID enabled real-time manufacturing system which will incorporate five functions. These five functions will be integrated into an android based interface which reads and writes data to a cloud based database in real time.

With RFID technology, tags, products, materials, parts, tools and so on can’t get lost in a manufacturing facility. And you don’t need people with scanners walking around trying to find and . This research aimed to develop and test an integrated industrial information system, the CSR-OMO-PL, through hardware, software and RFID technology for real-time integration and optimisation in footwear production lines, resulting in visibility and interoperability during manufacturing execution. The radio frequency identification (RFID) technology is applied in a mixed-model assembly line to facilitate operational functionalities of the manufacturing execution system (MES), including data collection, document control, labor management, production process control, and performance analysis.

Taking the textile industry as object, the design of manufacturing execution system based on RFID is presented by this paper. And it provide perfection system solution for enterprise realizing real-time informatization.This paper introduces an RFID-enabled real-time manufacturing execution system (RT-MES) for improving DM shop-floor management level in the perspective of illustrating the RT-MES software design and implementation.

empty nfc card

RFID in Manufacturing

RFID

contact card nfc

Enhancing Manufacturing Efficiency and Control with RFID

NFC stands for Not Factory Cut. The cards are hand cut into the shape and size of a normal MTG card from an Uncut sheet of cards. Uncut sheets are given away as prizes for .

manufacturing execution system rfid|Enhancing Manufacturing Efficiency and Control with RFID