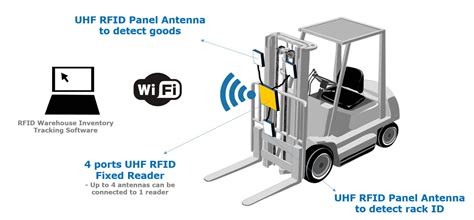

rfid inventory location tracking RFID can be used in any application where you need to identify, locate and track products, assets or materials. It’s often used in warehouses, distribution centers, and retail to automate inventory and eliminate manual barcode scanning and cycle counts.

Photo by 12photostory on Unsplash. Step-1: Add NFC Permission to AndroidManifest.xml. To use NFC in your Android app, you need to add the NFC permission to your AndroidManifest.xml file. Open your .

0 · rfid warehouse tracking system

1 · rfid labels for inventory tracking

2 · rfid inventory tracking software

3 · rfid inventory tracker

4 · rfid for warehouse inventory

5 · rfid based inventory tracking system

6 · rfid based asset tracking system

7 · rfid asset tracking software download

Step 1. Go to Settings > Connections > NFC and contactless payments. Step 2. Tap Contactless payments, and then select your preferred payment app. * Image shown is for illustration purposes only. Step 3. Additional payment apps can .

RFID Inventory Management is a system that leverages RFID tech for monitoring and managing items in your inventory. Adopting RFID injects speed, precision, and efficiency into your inventory tracking. It keeps you in the loop, registering every item’s exit or entry in real time. Radio frequency identification (RFID) inventory tracking and management is a system that uses radio waves to transmit data from RFID tags to RFID readers, which process the information from the tags to update inventory databases. RFID Inventory Management is a system that leverages RFID tech for monitoring and managing items in your inventory. Adopting RFID injects speed, precision, and efficiency into your inventory tracking. It keeps you in the loop, registering every item’s exit or entry in real time.

rfid tracking vehicles

From real-time location tracking to automated inventory management, RFID enhances asset tracking processes and improves overall operational efficiency. The future of asset location and tracking with RFID looks promising, with advancements in technology, integration with IoT, and growing adoption across industries. Radio frequency identification (RFID) inventory tracking and management is a system that uses radio waves to transmit data from RFID tags to RFID readers, which process the information from the tags to update inventory databases.

RFID can be used in any application where you need to identify, locate and track products, assets or materials. It’s often used in warehouses, distribution centers, and retail to automate inventory and eliminate manual barcode scanning and cycle counts. Thankfully, asset tracking solutions like Radio-Frequency Identification (RFID) can take inventory management to the next level and eliminate these issues. If this is your first time assessing RFID technologies for your inventory management, you’ve come to the right place. RFID tracking involves attaching an RFID tag loaded with data, including name, condition, amount, and location, to relevant assets. The RFID reader captures the stored data through pulsating.

RAIN RFID-enabled location tracking can change everything by delivering near-100% inventory visibility to warehouse and DC operators. How? RFID tags attached to products passively transmit real-time location data to networked readers, which update the inventory database in real time. How Does RFID Work for Inventory Tracking? An RFID system typically consists of three main components: • RFID Tags: These small electronic tags are attached to individual items or containers in your inventory. They contain a .

Inventory Management: RFID simplifies inventory procedures by boosting real-time tracking of product tags, reducing errors, and improving accuracy. Supply Chain Optimization: Extensively applied in supply chain management, RFID monitors the movement of goods, leading to improved visibility, reduced delays, and optimization of the supply chain. RFID technology is commonly used for location tracking in inventory management. It allows for the instant scanning and identification of all tagged objects and people, which increases efficiency and saves time. RFID Inventory Management is a system that leverages RFID tech for monitoring and managing items in your inventory. Adopting RFID injects speed, precision, and efficiency into your inventory tracking. It keeps you in the loop, registering every item’s exit or entry in real time. From real-time location tracking to automated inventory management, RFID enhances asset tracking processes and improves overall operational efficiency. The future of asset location and tracking with RFID looks promising, with advancements in technology, integration with IoT, and growing adoption across industries.

Radio frequency identification (RFID) inventory tracking and management is a system that uses radio waves to transmit data from RFID tags to RFID readers, which process the information from the tags to update inventory databases.RFID can be used in any application where you need to identify, locate and track products, assets or materials. It’s often used in warehouses, distribution centers, and retail to automate inventory and eliminate manual barcode scanning and cycle counts.

Thankfully, asset tracking solutions like Radio-Frequency Identification (RFID) can take inventory management to the next level and eliminate these issues. If this is your first time assessing RFID technologies for your inventory management, you’ve come to the right place.

RFID tracking involves attaching an RFID tag loaded with data, including name, condition, amount, and location, to relevant assets. The RFID reader captures the stored data through pulsating.RAIN RFID-enabled location tracking can change everything by delivering near-100% inventory visibility to warehouse and DC operators. How? RFID tags attached to products passively transmit real-time location data to networked readers, which update the inventory database in real time. How Does RFID Work for Inventory Tracking? An RFID system typically consists of three main components: • RFID Tags: These small electronic tags are attached to individual items or containers in your inventory. They contain a .

Inventory Management: RFID simplifies inventory procedures by boosting real-time tracking of product tags, reducing errors, and improving accuracy. Supply Chain Optimization: Extensively applied in supply chain management, RFID monitors the movement of goods, leading to improved visibility, reduced delays, and optimization of the supply chain.

rfid warehouse tracking system

NFC tag readers play a crucial role in this ecosystem by enabling the reading of NFC tags, which are small chips embedded in objects that transmit information when brought into close proximity with an NFC-enabled device. .

rfid inventory location tracking|rfid inventory tracking software