rfid tags surgical instruments An RFID chip and antenna can be embedded into metal surgical tools during the manufacturing process and sealed with a biocompatible sealant that can survive sterilization, allowing tools to be tracked during and after surgery. What to do with your first-generation Oyster card Transfer credit and/or season .

0 · medical device rfid tags

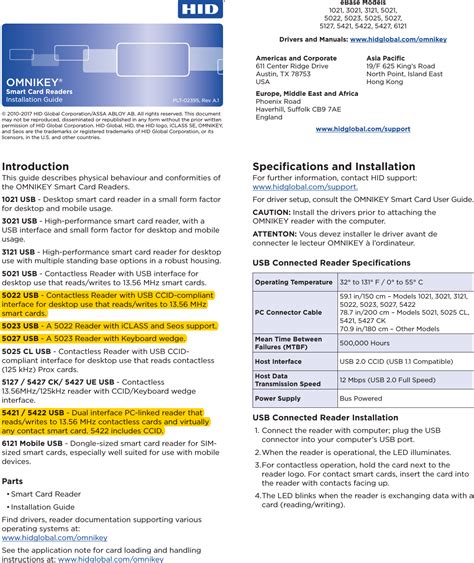

1 · hid rfid manual

2 · hid medical grade tags

3 · hid medical grade rfid

UICC Universal Integrated Circuit Card VCSP Visa Chip Security Program VMPA Visa Mobile Payment Application 1.3 Definition of Terms Term Description Reader A terminal that reads .

An RFID chip and antenna can be embedded into metal surgical tools during the manufacturing process and sealed with a biocompatible sealant that can survive sterilization, allowing tools to be tracked during and after surgery.In surgical instrument tracking, RFID tags firmly attach to each instrument, automatically .An RFID chip and antenna can be embedded into metal surgical tools during the manufacturing process and sealed with a biocompatible sealant that can survive sterilization, allowing tools to be tracked during and after surgery.

In surgical instrument tracking, RFID tags firmly attach to each instrument, automatically identifying and recording every link from cleaning, disinfection, storage, to use, and recycling. These benefits primarily reflect:Embed RFID tags into medical devices to prevent counterfeiting, leverage auto calibration, track assets, and protect patients. Used by medical OEMs.RFID tagging of individual surgical instruments allows hospitals to document each instrument’s vital statistics (image, name, manufacturer, manufacturer’s ID number, date of purchase, number of sterilization cycles, repair history, and location).

By embedding RFID tags into surgical instruments, you can help healthcare providers in a number of areas. First, RFID can help achieve real-time visibility by providing the constant monitoring of instrument location, enabling immediate identification of missing items.Realize the surgical instrument tracking with Murata RFID. We offer a safety operation and better work efficiency. Here are examples of the challenges and solution to tracking surgical instruments and medical devices.

Improve the management of surgical instruments with automated tracking. Our sterile services tracking solution provides live data on the availability of endoscopes and surgical trays in storage and theatre areas to improve logistics, efficiency and patient safety. Using RFID to manage surgical instruments is a relatively new application that involves a number of challenges. When developing your business case, assess your workflow and all the areas in which you will need to establish read points.Instrument RFID Tags & Scanners. RapID INNOVATIONS (patents issued/pending or proprietary): Radio Frequency Identification (RFID) Instrument Tagging; Real-time Mat Scanners; Real-time OR Table Scanner (Smart Table) Hand-held scanners (off the shelf back-up)

medical device rfid tags

Surgical instrument tracking solution with passive XS RFID tags along with Integrated Business Systems and Services (IBSS), ThingMagic EPC Gen 2 Mercury5 and Astra RFID readers, and an RFID portal from Industrial Portals. Benefits. Eficient Inventory Management. Loss Reduction of High Cost Equipment. Improve asset utilization.An RFID chip and antenna can be embedded into metal surgical tools during the manufacturing process and sealed with a biocompatible sealant that can survive sterilization, allowing tools to be tracked during and after surgery.In surgical instrument tracking, RFID tags firmly attach to each instrument, automatically identifying and recording every link from cleaning, disinfection, storage, to use, and recycling. These benefits primarily reflect:Embed RFID tags into medical devices to prevent counterfeiting, leverage auto calibration, track assets, and protect patients. Used by medical OEMs.

RFID tagging of individual surgical instruments allows hospitals to document each instrument’s vital statistics (image, name, manufacturer, manufacturer’s ID number, date of purchase, number of sterilization cycles, repair history, and location). By embedding RFID tags into surgical instruments, you can help healthcare providers in a number of areas. First, RFID can help achieve real-time visibility by providing the constant monitoring of instrument location, enabling immediate identification of missing items.

Realize the surgical instrument tracking with Murata RFID. We offer a safety operation and better work efficiency. Here are examples of the challenges and solution to tracking surgical instruments and medical devices.

Improve the management of surgical instruments with automated tracking. Our sterile services tracking solution provides live data on the availability of endoscopes and surgical trays in storage and theatre areas to improve logistics, efficiency and patient safety. Using RFID to manage surgical instruments is a relatively new application that involves a number of challenges. When developing your business case, assess your workflow and all the areas in which you will need to establish read points.Instrument RFID Tags & Scanners. RapID INNOVATIONS (patents issued/pending or proprietary): Radio Frequency Identification (RFID) Instrument Tagging; Real-time Mat Scanners; Real-time OR Table Scanner (Smart Table) Hand-held scanners (off the shelf back-up)

hid rfid manual

image of nadra smart card

infinity best smart card driver windows 7 64 bit

$89.00

rfid tags surgical instruments|medical device rfid tags